新南威尔士大学的科学家从大自然中汲取灵感,开发了一种新方法来进行化学还原 - 一种工业过程,用于生产对现代社会至关重要的燃料和化学物质。

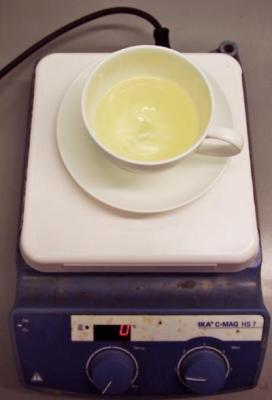

The new catalyst-based approach to chemical reduction works well at room temperature and in air -- and can even be carried out in a teacup. (Credit: University of New South Wales )

The new catalyst-based approach to chemical reduction works well at room temperature and in air -- and can even be carried out in a teacup. (Credit: University of New South Wales )

他们基于催化剂的方法具有很大的优势,即它使用便宜,可补充的试剂,并且在室温和空气中效果很好 - 因此,甚至可以在茶杯中安全地进行。

该研究由UNSW化学学院副教授Stephen Colbran领导的团队发表,已出版为著名杂志Angewandte Chemie的封面。他们设计的催化剂模拟了催化降低的天然酶的活性,例如酵母中的酒精脱氢酶,有助于从糖中产生酒精。

Colbran博士说:“人类生存的基础是工业化学减少过程,但是不可持续的,因为它们不可逆地消耗了以高昂的能源成本制造的试剂。”“我们认为,我们的新仿生设计可能在化学还原方面具有广泛的应用。”

Chemical reduction involves the addition of electrons to a substance, and is the basis of making many fuels, including the sugars that plants produce during photosynthesis.

In industry, molecular hydrogen and reactive reagents such as sodium borohydride are used as reducing agents during the production of pharmaceuticals, agrichemicals and ammonia for fertiliser.

Colbran博士说:“这些物质的生产成本高昂,导致二氧化碳释放,并且很难处理和存储。”“因此,我们决定看大自然,看看自然是如何做到的。”

The team combined a transition metal complex containing rhodium with a Hantzsch dihydropyridine - an organic donor of a hydride ion similar to biological nicotinamides - to produce the new bio-inspired catalyst. They tested it on a common process - reduction of imines - and were surprised to find it worked in ambient conditions with more than 90 per cent efficiency in most cases.

Dr Colbran even tested it out in a teacup. "I thought it would be a bit of fun. And it makes a serious point – our catalyst system is very easy to use."

巧合的是,这项研究恰好是一个世纪之后,阿尔弗雷德·沃纳(Alfred Werner)因其在过渡金属综合体的结构上的工作而获得诺贝尔化学奖。他的博士主管Arthur Hantzsch也发现了合成二氢吡啶的道路。

"It has only taken 100 years to combine the work of doctoral adviser and student into one molecule," Dr Colbran says.

未来的目标是尝试将温室气体(二氧化碳碳)转换为可再生燃料,甲醇,更有效地。

Source:http://www.unsw.edu.au