2018年12月13日

使用3D打印和其他添加剂生产方法,可以创建具有以前无法想象的复杂性内部结构的材料。欧洲杯足球竞彩对于轻质结构来说,这也令人兴奋,因为它可以开发具有最大可能占用内部空隙的材料(以使材料尽可能轻巧),但同时尽可能强。欧洲杯足球竞彩为了实现这一目标,必须智能组织内部结构以提高效率。

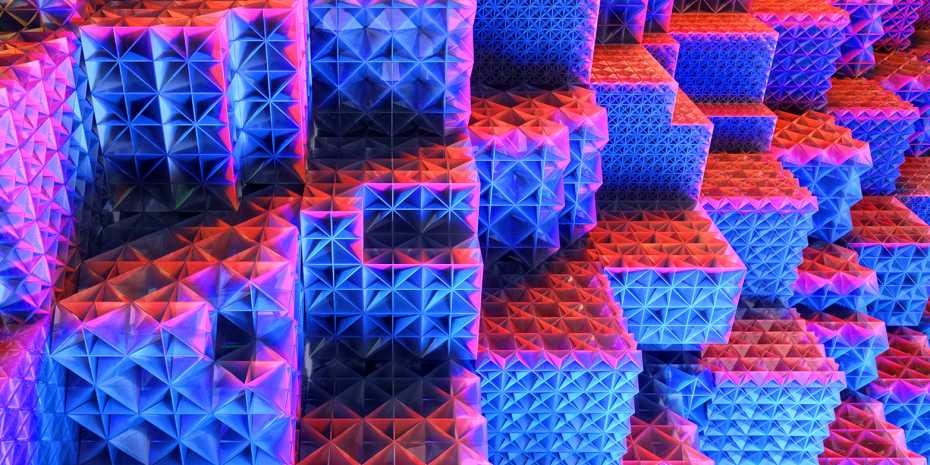

Plate-lattices will be the design of choice for future lightweight porous materials (Visualizations: ETH Zurich/Marc Day)

Plate-lattices will be the design of choice for future lightweight porous materials (Visualizations: ETH Zurich/Marc Day)

A study team from苏黎世and MIT led by Dirk Mohr, Professor of Computational Modeling of Materials in Manufacturing, has designed and fabricated material architectures that are similarly strong in all three dimensions and concurrently very stiff.

It is possible to establish mathematically just how stiff materials with internal voids can hypothetically become; Mohr’s structures have been demonstrated to come very close to this theoretical maximum stiffness. To put it differently, it is virtually impossible to create other material structures that are stiffer for the specified weight.

盘子更换桁架

A typical feature of the design is that the stiffness in the material’s interior is attained through plate-lattices instead of trusses.

“桁架原理很老;长期以来,它一直用于半缠结的房屋,钢桥和钢铁塔,例如埃菲尔铁塔。

我们可以透过桁架晶格,因此通常被视为理想的轻质结构。”莫尔教授说。“但是,使用计算机计算,理论和实验测量结果,我们现在建立了一个新的板块晶体结构家族,其比相同的重量和体积的桁架局势高达三倍。”此外,不仅是这些结构的刚度(抗弹性变形)达到理论上的最大值,还达到其强度(对不可逆变形的抗性)。

ETH科学家主要在计算机上开发了这些晶格,在此过程中计算其性能。然后,他们使用3D打印从塑料中以千分尺尺度创建它们。Mohr强调,这种设计的好处通常是适用的 - 对于所有组成材料以及所有长度尺度,从非常小(纳米尺寸)到非常大的尺度。欧洲杯足球竞彩

Ahead of their time

Mohr and his research team’s new lattices are futuristic: presently, manufacturing with 3D printing is still fairly expensive.

If these kinds of lattices were to be additively manufactured from stainless steel today, they would cost as much per gram as silver.但是,当增材制造技术准备大规模生产时,突破将实现。轻巧的结构(当前的成本都限制了飞机制造和空间应用的实际用途,也可以用于重量起作用的各种应用程序。

Dirk Mohr, Professor of Computational Modeling of Materials in Manufacturing, ETH Zurich

Besides making structures lighter, the many voids also minimize the amount of raw materials required, and thereby also the material costs.

Mohr说,有无限的潜在应用。医疗植入物,超轻车辆结构和笔记本电脑套管仅是许多潜在示例中的三个。

当时间合适时,一旦大规模制造了轻质材料欧洲杯足球竞彩,这些周期性板格将是选择的设计。

Dirk Mohr, Professor of Computational Modeling of Materials in Manufacturing, ETH Zurich