韩国长旺国立大学的研究人员团队在《杂志》上发表了一项研究欧洲杯足球竞彩材料研究与技术该研究调查了在机床再制造中使用电弧添加剂制造(WAAM)。

Study:Repair of damaged parts using wire arc additive manufacturing in machine tools。Image Credit: Stock-Asso/Shutterstock.com

Manufacturing is highly dependent on reproducibility which in turn is dependent on mechanical parts that perform in their intended usage. At times these parts may malfunction or require repair or replacement. This is true across a broad range of industries such as automotive, aerospace, and machine tools, therefore, research on damaged machine tool parts is required for repair/replacement.

然而,这样的部分可以由复杂的几何形状组成,这些几何形状很困难,时间/劳动力密集是使用传统过程(包括滚动,锻造和铸造)制造的。期刊上的一项新研究欧洲杯足球竞彩材料研究与技术considers how wire arc additive manufacturing (WAAM) can be used for machine tool remanufacturing.

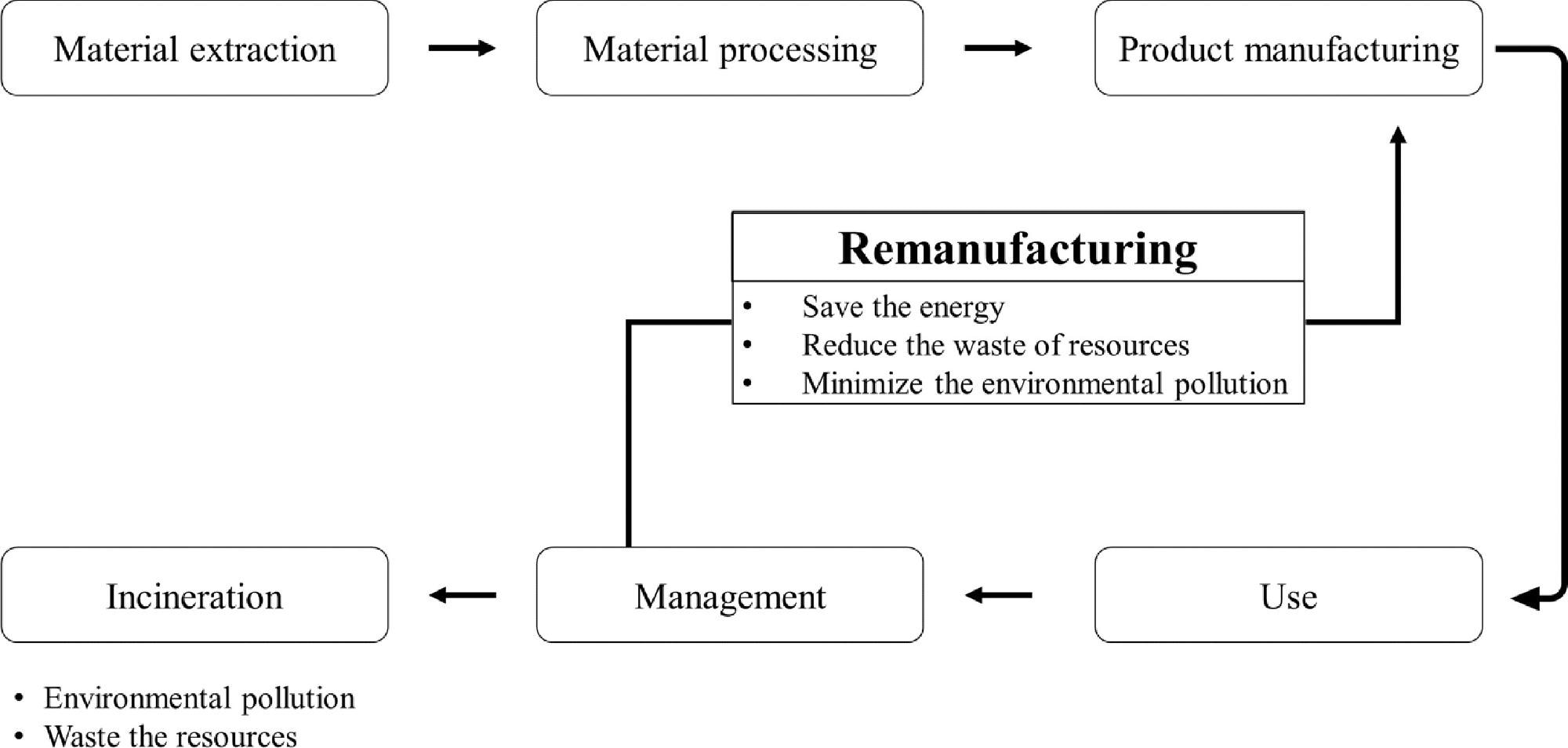

Lifecycle of a product for remanufacturing. Image Credit: Lee J-H et al., Journal of Materials Research and Technology

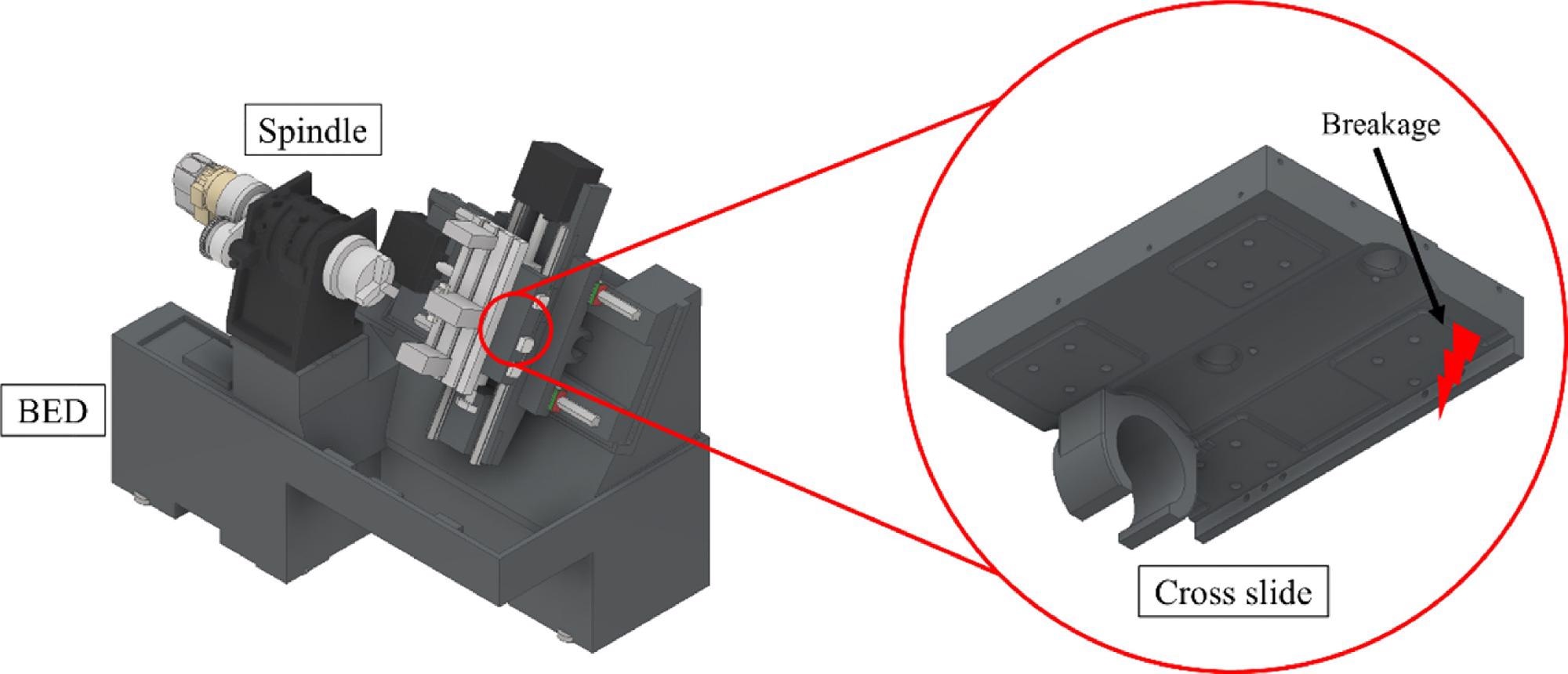

“In general, these parts are often damaged owing to falls of the workpieces and the inexperience of workers; the cross slide is one of the parts damaged most often in a lathe,”长华旺国立大学机电一体化研究中心的Dong-Hyeon Kim解释说。

Accordingly, the researchers selected the cross slide as an example for their study in order to demonstrate how effective WAAM could be in the repair of mechanical tools.

什么是瓦姆?

WAAM, or wire arc additive manufacturing is a 3D printing technique that utilizes arc welding to build up the component part in a sequence of layers. Belonging to the direct energy deposition (DED) family of additive manufacturing (AM) processes.

WAAM将AM与气体金属电弧焊接(GMAW)结合在一起,这是一种用于使用电弧熔化金属零件的焊接过程。通常,使用WAAM的零件生产由自动焊接机器人组进行融化,以形成复杂和复杂几何形状的3D零件。

WAAM以多种方式优于常规制造过程和其他DED技术。其中包括具有目标材料应用,额外的设计自由,较低的启动成本(比减法CNC制造便宜60%)以及零件中的扭曲或畸变的最小扭曲或畸变。

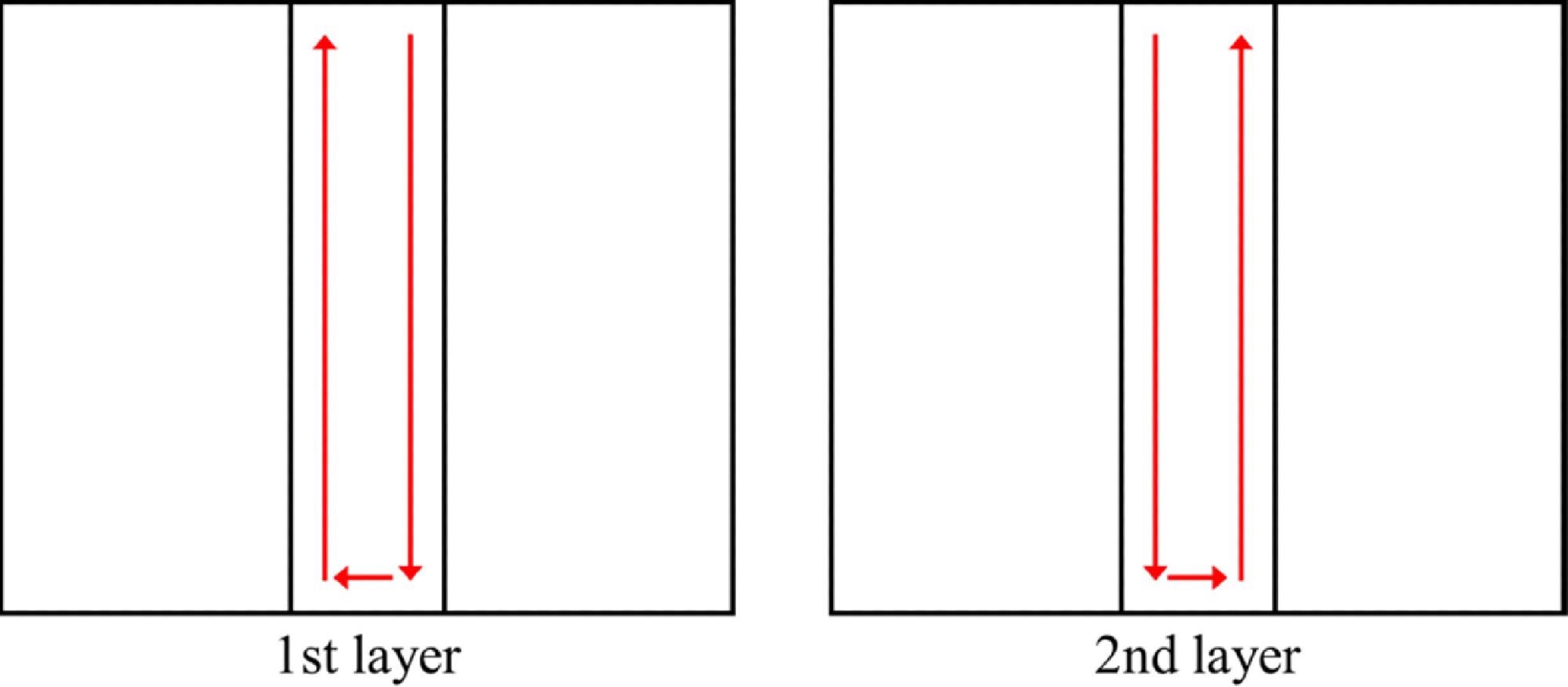

实验中用于参数测定的沉积路径。Image Credit: Lee J-H et al., Journal of Materials Research and Technology

用WAAM修理零件

Generally speaking, there are two kinds of defects in machine tool parts: structural defects and morphological defects. For the purpose of this study, Kim and his colleagues only considered morphological defects which include cracks, holes, notches, and surface marks.

As such, the damaged parts of a cross slide were repaired with the application of WAAM in machine tool remanufacturing. The cross slide was initially produced using gray cast iron, and nickel wire was employed as the WAAM deposition material for repair. A different material was selected for repair to simplify the analysis of the microstructure, chemical composition, and mechanical property of the repaired parts.

团队决定部分切割基材的表面平坦,以便可以在受损区域均匀地应用镍沉积材料:欧洲杯足球竞彩“镍电线被用作沉积材料来抑制WAAM中的裂缝和毛孔,”欧洲杯足球竞彩stated Kim.

Repair of the cross slide was successfully achieved by filling the damaged area using WAAM at different current speeds set as parameters, 100 A, 180 A, and 260 A respectively.

The repaired cross slides were then subsequently analyzed at each of the current speeds to assess overall performance and properties.

Example of the damaged parts in the lathe. Image Credit: Lee J-H et al., Journal of Materials Research and Technology

该小组发现,在180和260 a处维修的零件与该物种的零件并不相同,该物种的硬度与铸铁基板的硬度增加了17%,而维修时260的物种的硬度增加了15%。

The researchers determined that post-processing was essential for adjusting the specifications of the original parts after AM was performed: Post-processing of the repaired specimen was performed with the same specifications as those for the original parts. Finally, the repair was successfully carried out on the original parts,”说明金。

Overall, the study demonstrates the successful application of WAAM for repairing machine tool parts using alternative materials on a cast iron substrate. The team state that this method can be applied to various mechanical parts including turbine blades, impellers, and machine tools. This opens up the window of opportunity for using WAAM in the repair of parts across a range of industries.

参考和进一步阅读

Lee J-H, Lee C-M, Kim D-H, Repair of damaged parts using wire arc additive manufacturing in machine tools,杂志欧洲杯足球竞彩材料研究与技术,https://www.欧洲杯线上买球sciendirect.com/science/article/pii/s2238785421014356?via%3dihub

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of theTerms and conditionsof use of this website.